About Ejectors and Systems

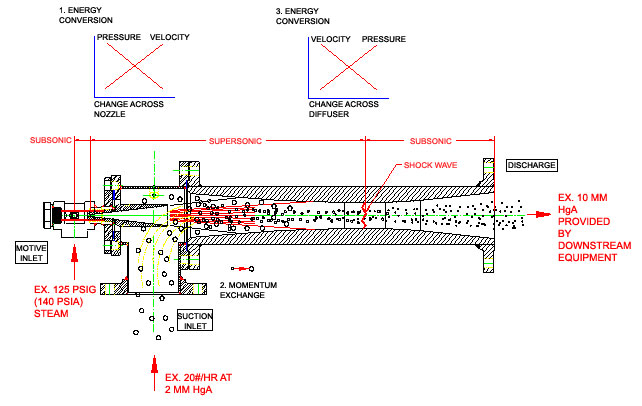

An ejector is a device that uses one fluid to do work directly on another fluid. The two geometries are called a nozzle and a diffuser. The three major connections are motive, suction and discharge. The main components are nozzle head, nozzle, and suction head/diffuser or suction head and diffuser.

An Ejector performs like a compressor. It converts the pressure energy of steam (or some other pressurized fluid) into velocity energy. It then makes a momentum exchange with the suction fluid. The mixture is slowed down and converted back to pressure energy in the diffuser. We say the mixture is compressed up to the next interstage pressure (a higher absolute pressure) in a multistage system where it is condensed (as soon as the given cooling water temperature allows). The non-condensables are then compressed further by another ejector (or liquid ring vacuum pump) until the appropriate discharge pressure is reached (typically atmospheric pressure). Intercondensers are put between stages for the purpose of removing condensables (particularly the ejector steam just used for a compression) so that the next compressing device has a smaller load and uses less energy. Intercondensers therefore are mainly used for steam conservation.

Ejectors are labeled (in a multistage system) backwards in the alphabet starting with the last (Z) stage (ejector discharging to atmospheric pressure). Condensers are labeled by the ejectors connected to them (e.g. XY, YZ, ZA).

Ejectors have a positively sloping performance curve of suction fluid mass flow (x) vs. absolute suction pressure (y). Their capacity is a function of scale (size) and they will add their capacities when installed in parallel, proportionally to the size of each.

An ejector's compression ratio is a function of the mass flow per diffuser bore area. Beyond a typical maximum (say 10:1) the available suction pressure is a function of the number of stages in series in a system. Ejectors have a distinct maximum ability to withstand discharge pressure (for a given total of motive plus suction flow) beyond which the absolute suction pressure "breaks" or rises rapidly.

|

|