|

|

|

|

Fluid Separation Systems

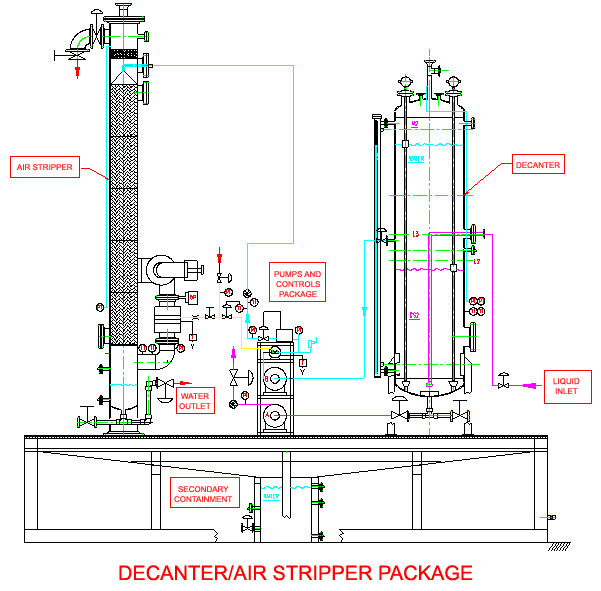

ThermoSepTM

Separating and Air Stripping of Liquids

To Remove Immiscible Contaminants

Operation

The liquid stream to be treated is pumped into the Decanter and gravity separated. Float sensors are set to determine the pumping time and duration for each phase. The heavy phase is pumped out of the bottom for storage and reuse. The water (with some contaminate still saturated in it) is heated and pumped to an Air Stripper. Warm air is provided to mix with the water and absorb the contaminate. All valves and controls are provided for automatic and safe handling of all fluid streams. Secondary containment is provided in a full base pan with detection for the presence of the heavy phase (from leakage or spill). Density is monitored in the liquid stream that is pumped to the Air Stripper to stop an inadvertent heavy phase transfer.

Advantages

- Separation and treatment in the same package.

- Complete Skid mounted packages of mechanical equipment provided for system safety and ease of installation.

- No contaminated condensate stream for disposal (as with a steam stripper).

- Air flow is adjusted for the proper overhead concentration to avoid an explosive mixture or environmentally unacceptable concentrations.

Features

- ASME Code Section VIII, Div. 1 Stamped vessels, 100 Psig design pressures

- ANSI B31.3 piping, 150 Psig design pressure

- Class 1, Div. 1, Group C&D equipment

- All corrosion resistant construction (316L SS or Hastelloy), Kynar packing

- High and low level alarm switches throughout

- Full set of back up level switches and detection devices for safety interlocks

- Large capacity Decanter with eduction inlet pipe, O2 sensor and weighted vent valve

- Fire Safe air actuated ball valves, air to open, double sealed and vented

- Seal less mag drive pumps

- Full secondary containment with passive water padding

- Welded piping, 150# flanged connections, Gylon 3500 gaskets, SS fasteners

- Pressure and temperature transmitters on both vessels

- Local pressure, temperature, flow, and level indicators throughout

|

|

4611 S. University Dr. BLDG 109, Davie, FL 33328

508-486-9800, www.thermosysinc.com

email: service@thermosysinc.com National cellular: 508-561-2100 (24x7)

|